In the intricate tapestry of supply chain management, efficiency and speed are integral threads that determine the vibrancy and effectiveness of operations. Among various logistics strategies employed to achieve these goals, cross docking stands out as a transformative practice. Let’s delve into the realm of warehouse cross docking, understand its process, and explore the myriad benefits it brings to the table.

The Old Warehouse Method

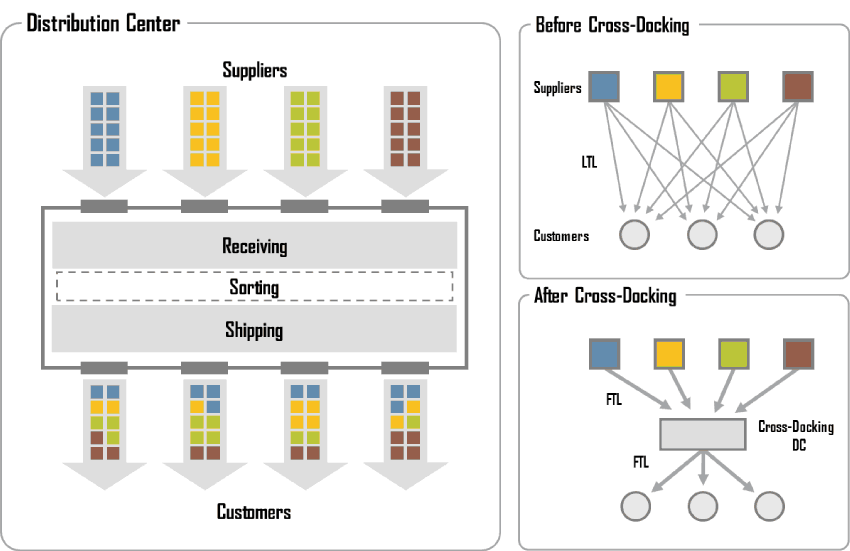

Traditional warehousing and delivery is a thing of the past, the more convenient and logical option is cross docking. The old process required you to take the shipments from point A and unload them at a warehouse for a few days and then sending them off to their final destination. It would essentially break the chain and take twice the manpower to do. Cross docking eliminates the need for storage and delays. With cross docking, we unload goods from an inbound delivery and load them directly onto an outbound delivery vehicle. The entire process can be as short as an hour or as long as 24 hours. WHSE Hub is an expert on cross-docking and we have created tech-savvy solutions for our in-house cross-docking.

Unraveling the Concept of Cross Docking

Cross docking is a logistics procedure where incoming shipments are directly transferred to outbound gates with minimal to no storage in between. In a typical cross-docking scenario, goods arrive at the warehouse, and rather than being stocked in storage areas, they are immediately prepared for shipment to the next location. This process significantly reduces the need for storage space and time, aligning with the mantra of ‘just-in-time’ delivery.

Advantages of Cross Docking

- Expediting the customer order: With less time in storage, items get to customers faster. There is a high turnover for products than with the old, outdated system.

- Reduction in delivery time: Often times, cross docking facilities are located near the final destination, greatly reducing delivery times.

- Reduction of material handling: Using the new method reduces the amount of activity taken on a shipment. There is no more need for picking and put away. The only material handling needed is unloading, staging and loading.

- Reduction in costs: Packaging and storing costs are reduced tenfold. There is no longer a need for storage and packaging has become automated bringing costs to a minimum. Transportation and distribution costs are also reduced. Multiple loads can be transported together, so instead of two half-empty loads being transported separately, there will be one full load being transported. There is no longer a need for multiple stops and that means fewer miles are being traveled cutting down on expenses for fuel and vehicle service.

- Decrease in damages: In traditional warehouse scenarios, clients would fear that inventory was being mishandled and arrived damaged. However, using cross docking there is no need to store items. They go from one delivery to another cutting out the downtime in storage.

- No need for warehouse: There is no need for additional warehouse space. Cross docking requires its own specialized facility. It is much easier to construct than a warehouse and can often be converted from unused warehouse space. It requires less square footage which provides savings for all parties involved.

- Faster screening: Using proprietary software and in-house protocols, the screening process is minimal.

- Customer satisfaction: Customers hate getting the wrong order or even worse a damaged product. During the cross docking process, staff can check for any damage that may have occurred during the transport process. It serves as a secondary source for ensuring the customer receives fewer damages. The less that delivery costs, the less the end customer will have to pay. Everyone loves saving money.

The benefits of cross docking are plenty especially when done correctly. At this rate, the traditional methods will soon be gone with the wind.

Final Thoughts

While cross docking offers numerous benefits, its implementation requires careful planning, coordination, and a suitable technological infrastructure to track the swift movement of goods. Despite the challenges, when executed effectively, it can be a game-changer, streamlining operations, cutting costs, and enhancing customer satisfaction.

As businesses strive to keep pace with the ever-evolving demands of consumers and the dynamic nature of global trade, strategies like cross docking are no longer just an option but a necessity. They represent the relentless pursuit of efficiency in the logistics landscape, underscoring the power of smart strategies in warehouse management.

Contact US

For more information, follow us each week for the latest transportation industry news or contact WHSE Hub here. Take control of your freight with an Asset-Based 3PL Warehousing Company that can keep your cargo secure. Request a free quote today!